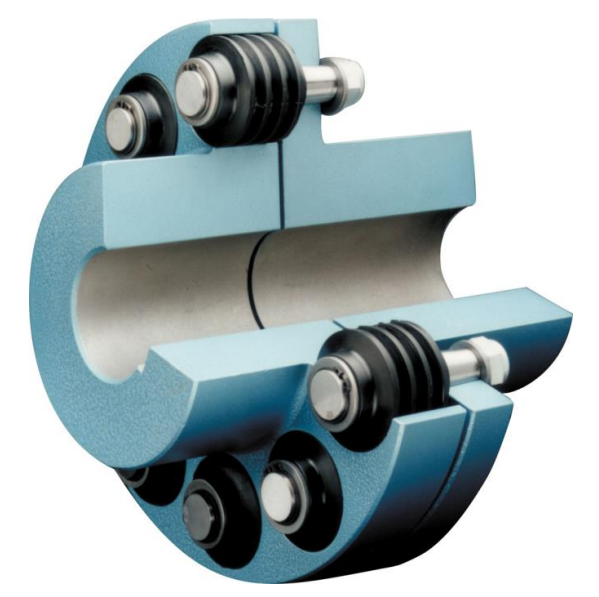

Backstop

When the gradient of the conveyor is large and the upward transportation is loaded, there is a tendency to reverse when the upward operation is stopped due to shutdown or failure of the driving device. When the conveyor belt reverses and the sliding force of materials is greater than the resistance

Exclusive salesman contact information:

0086 24 31976438

0086 24 31976439

Product details

When the gradient of the conveyor is large and the upward transportation is loaded, there is a tendency to reverse when the upward operation is stopped due to shutdown or failure of the driving device. When the conveyor belt reverses and the sliding force of materials is greater than the resistance caused by each friction of the conveyor, because the sliding force is greater than the resistance, the conveyor belt will produce a downward sliding acceleration, and the materials will accumulate at the tail of the conveyor, which will damage the conveyor belt and cause accidents in serious cases. In order to prevent the reverse movement of the conveyor and counteract this acceleration force, a backstop is applied.

1. It has large backstop torque and high reliability;

2. Long service life;

3. Light weight and convenient installation and maintenance;

4. Suitable temperature: - 40 ℃ ~ + 80 ℃, consult our company if it exceeds the range;

5. Allow free idling and sliding speed;

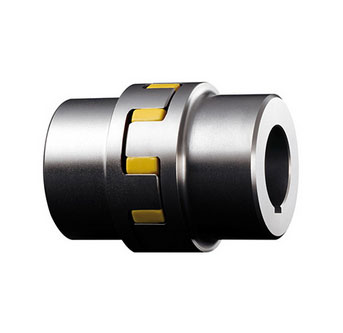

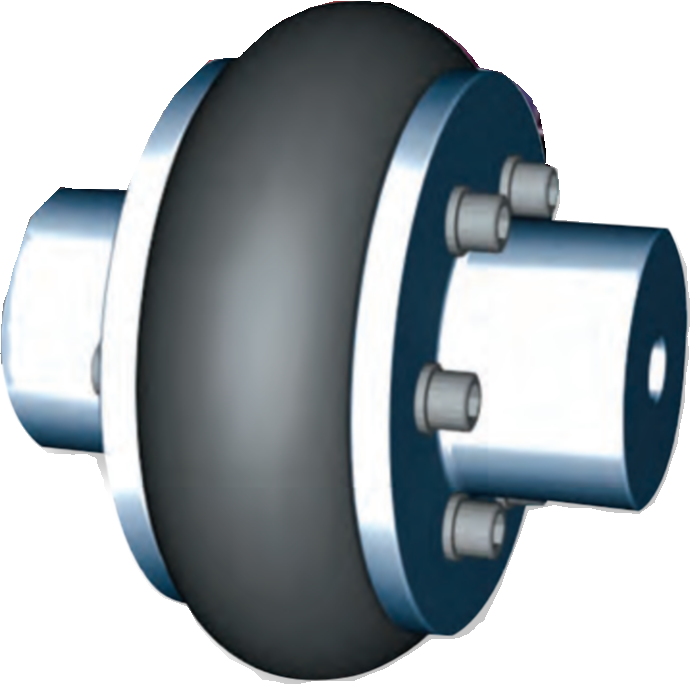

| type | : | WBC wedge type one-way clutch / WBF non-contact backstop / WBT low speed contact backstop / wbtz low speed contact backstop |

| application | : | It is widely used in reducer matching, coking plant and transportation machinery, conveyors, hoists, electric rollers and other mechanical equipment requiring backstop requirements. |

| industry | : | Metallurgy, mining, petroleum, chemistry, light industry, textile, steel plant, power plant, etc. |

中文版

中文版 English

English Русский Язык

Русский Язык Français

Français Español

Español